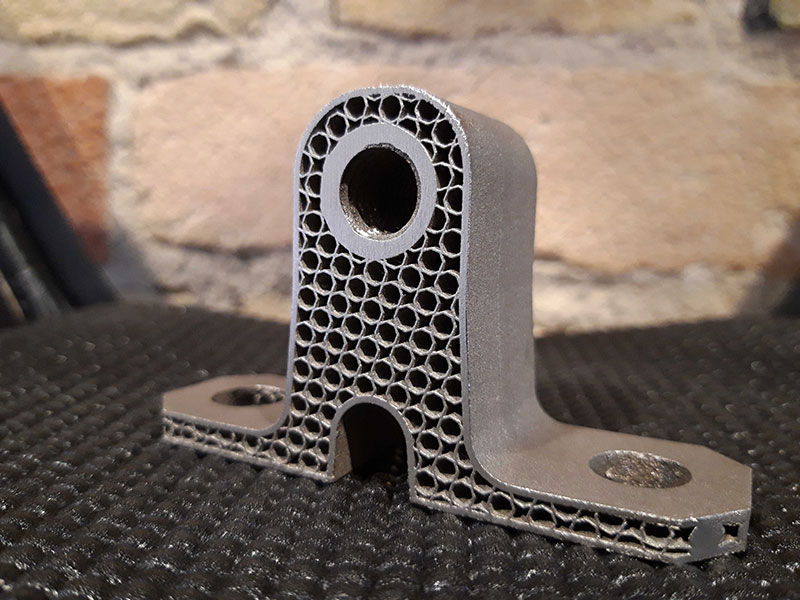

[vc_row][vc_column][vc_column_text]Lightweighting is a holistic design philosophy. It aims to save weight, material and energy while also ensuring, and even improving, the performance and efficiency of components and complete systems. This is achieved through load reduction and a switch to new construction materials. By reducing mass and the amount of material needed, and by using the right lightweight design, components’ carbon footprint can be significantly reduced before, during and after operation. The brand-new shapes and designs developed for lightweight designs, which are often based on those in nature, are difficult if not impossible to realise using conventional manufacturing processes. In order to advance lightweighting as a key enabling technology, it is therefore crucial to use new construction technologies such as additive manufacturing, and to develop these further. Lightweighting and additive manufacturing are thus two technologies that complement each other extremely well.[/vc_column_text][vc_column_text]Lightweighting is flagged up as a game-changing technology in Germany’s Coalition Agreement for the 19th legislative period, as well as in its Sustainability Strategy and 2030 Industrial Strategy. In order to actively promote lightweight construction, the Federal Ministry for Economic Affairs and Energy has set up a programme called the Technology Transfer Programme for Lightweighting (German abbreviation: TTP LB). The programme aims to establish lightweighting as a driver of innovation for sustainable business, and to make an important contribution to achieving the Federal Government’s climate targets. Funding of around 300 million euros is being made available for this purpose between 2020 and 2030.

The funding provided by the Federal Government is being used to support new technological developments, construction techniques and the use of new materials, projects focusing on resource efficiency and substitution, standardisation issues and demonstration projects with the overarching goal of reducing carbon emissions. In particular, the programme’s first funding line seeks to promote innovative design principles and technologies, such as additive manufacturing, as drivers and enablers of sustainable lightweighting. The focus is on optimising and automating lightweighting production processes (especially in additive manufacturing) in order to raise sustainability throughout the entire life cycle of the products.

Under the Technology Transfer Programme for Lightweighting, funding line 3 ‘Resource efficiency and substitution’ also offers plenty of scope for additive manufacturing projects. It aims to promote projects in which, for example, additive manufacturing processes are used to replace resource-intensive materials with more resource-efficient and lighter materials, and components can be produced directly on site. This reduces both time and carbon emissions as it eliminates the need for transport.

The Technology Transfer Programme for Lightweighting was successfully launched in April 2020 despite the considerable restrictions in place due to the coronavirus pandemic. Outlines for some 180 projects, for which over 60% funding is being provided by industry, were submitted by the first deadline (April 2020). These covered innovations that can be applied across a broad variety of different industries – from the automotive sector, to aerospace, through to medicine and construction. Full applications are now currently under way for about 60 of these projects. The next funding deadlines for innovative additive manufacturing processes for sustainable lightweighting are 1 October 2020 and 1 April 2021.

Detailed information can be found under TTP LB and Initiative Leichtbau des BMWi.[/vc_column_text][/vc_column][/vc_row]